PRODUCT

推荐产品

-

-

Ore color separator series Suitable for all kinds of ore color separation. According to...

Ore color separator series Suitable for all kinds of ore color separation. According to... -

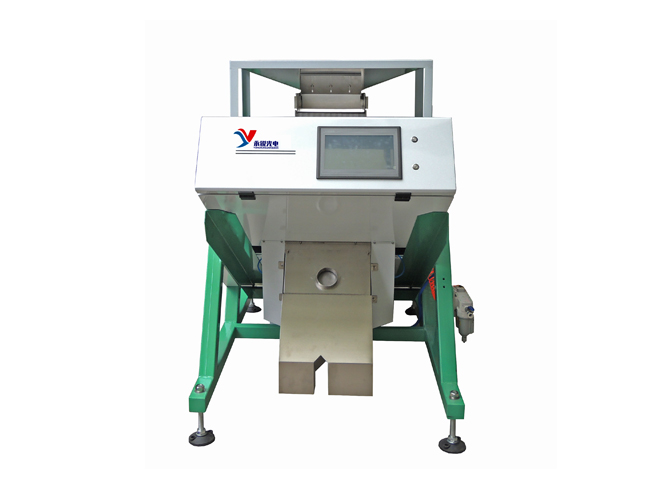

Plastic color sorter series Suitable for all kinds of plastic color separation. Accordin...

Plastic color sorter series Suitable for all kinds of plastic color separation. Accordin... -

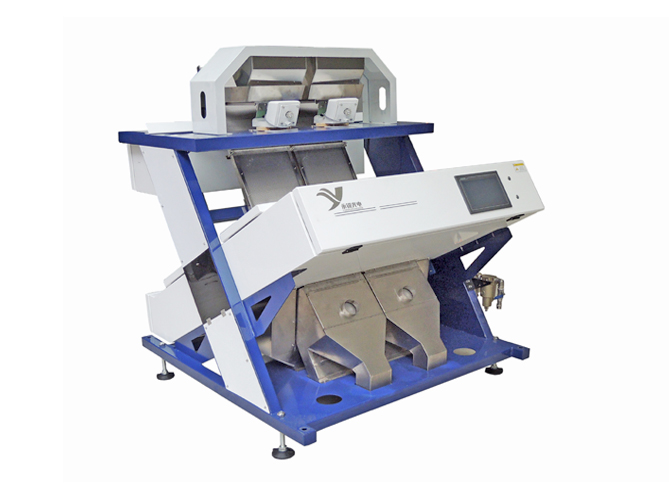

Assorted grain color sorter se It is applicable to the color selection of various grains. A...

Assorted grain color sorter se It is applicable to the color selection of various grains. A... -

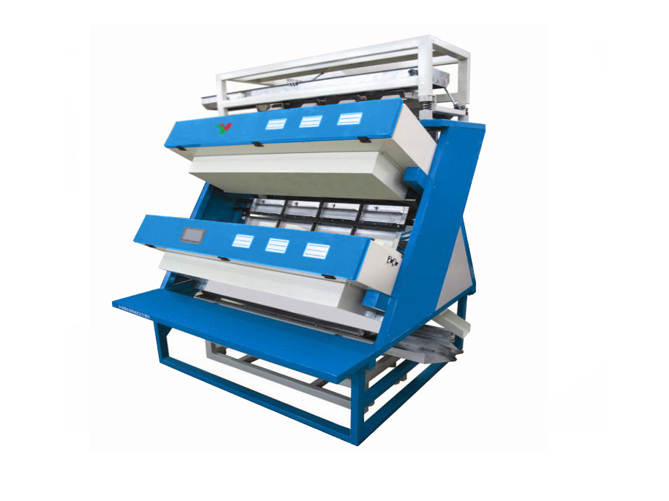

Large Beige sorter series Suitable for all kinds of rice color selection, according to...

Large Beige sorter series Suitable for all kinds of rice color selection, according to... -

Tea color sorter series Suitable for all kinds of tea color selection, according to ...

Tea color sorter series Suitable for all kinds of tea color selection, according to ... -

Bean color sorter series It is suitable for all kinds of bean color selection. Accord...

Bean color sorter series It is suitable for all kinds of bean color selection. Accord... -

Dry goods sorter series It is suitable for all kinds of dry goods color selection. A...

Dry goods sorter series It is suitable for all kinds of dry goods color selection. A... - Learn more products

-

Color selection application case

CASE

Yongrui is more than 1000 enterprises

Solved a variety of customer problems

MORE-

Yongrui yr series rice color sorter uses color CCD technology to remove impurities such as grass seed, mildew, half grain, water yellow, blackhead and stone from rice, effectively ...

-

A pepper processing plant; intelligent image acquisition and analysis technology, sorting pepper ring, Chaotian pepper, pepper stem removal, flower skin effective area removal, mul...

-

Yongrui peanut Beige sorter, a peanut processing factory, can complete two, three and four selections at the same time on a single machine, reducing the take out ratio. Germination...

-

Yongrui Y Series small artificial intelligence color sorter was used in a breeding center in Hebei Province. It can effectively replace the manual picking, and the live insects and...

-

It is used to remove impurities in the glass sand of a factory in Shandong Province. The new technology of "intelligent color" developed by Yongrui is adopted. By using optical ima...

- Jiangsu rice

- Some hot pepper

- Peanut meat

- Tenebrio molitor

- Shandong glass sand

- company information

- Industry News

-

Company information

Anhui Yongrui photoelectric technology shares with you the industries in which c

Color sorter is a kind of equipment which uses photoelectric detection technology to automatically sort out the differen...

+ DETAILS-

Ma'anshan color sorter Co., Ltd. | which is the famous color sorter supplier in

Ma'anshan color sorter Co., Ltd. | which is the famous color sorter supplier in Anhui? Anhui Yongrui Photoelectric Techn...[DETAILS]

07 2020-02 -

Daily precautions for color sorter | where can I sell the small color sorter wit

Daily precautions for color sorter | where is the small color sorter with preferential price? Anhui Yongrui Photoelectri...[DETAILS]

07 2020-02 -

What benefits do color sorters bring to enterprises in the production process

In the production process, what benefits do color sorters bring to the enterprise? Anhui Yongrui photoelectric Co., Ltd....[DETAILS]

07 2020-02

-

-

Industry News

Working principle of color sorter - product quality assurance of Yongrui photoel

Anhui supply color sorter - Yongrui photoelectric color sorter product quality assurance, Anhui Yongrui photoelectric in...

+ DETAILS-

What are some technical indicators of color sorter - good quality color sorter m

What are some technical indicators of the color sorter - the market price of the color sorter with good quality is Anhui...[DETAILS]

07 2020-02 -

Plastic color sorter series - want to buy color sorter

Plastic color sorter series - want to buy color sorter, Anhui Yongrui photoelectric technology. In order to ensure the r...[DETAILS]

07 2020-02 -

What are the installation requirements of beige sorter?

Large rice color sorter has been widely used in rice selection, and has been favored by many rice manufacturers, which i...[DETAILS]

25 2019-12

-